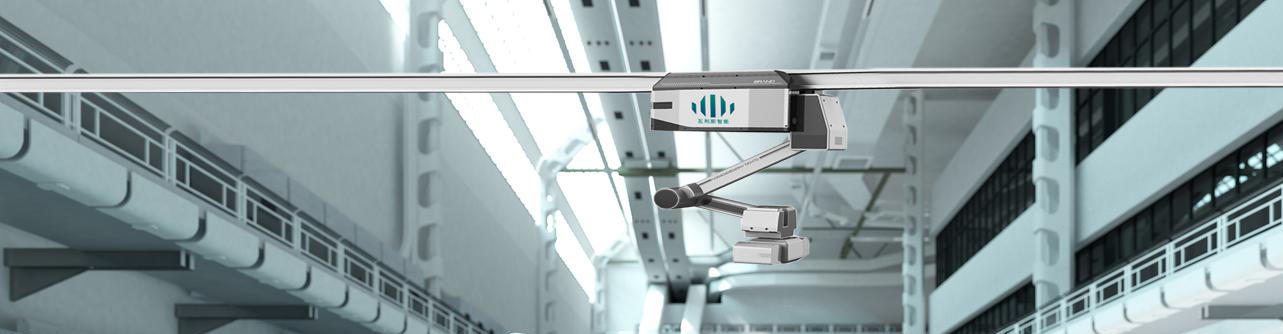

Drive control integrated machine

Classification:

product

- describe

- parameter

- size

-

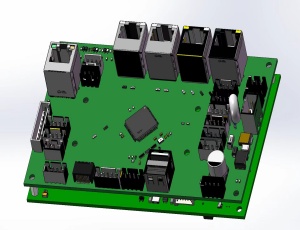

Specification Table V0.4 for Drive Control Controller Main control module work environment Temperature range: -40 ℃~+80 ℃ Relative humidity (%): 10% RH~90% RH without condensation Power supply parameters Power supply voltage The voltage range is 16-36V, independently powered Power protection The power input terminal has protection functions such as overvoltage, undervoltage, overcurrent, and short circuit. Indicator light source 1 unit working condition 1 unit Power on mode Power on/off Power on/off communication interface Isolation RS232 1 channel Isolation RS485 3-way Isolation CAN 2-way, 500KBPS Built in 120 Ω matching resistor. LAN 1 channel, 1000MBPS WIFI 1-channel adaptive dual frequency 4G 1 channel Antenna connector three Display interface 1 channel DSI Multimedia audio 1 output input signal data interface Isolation DI 8-channel digital input channel (NPN), There are two AB encoder interfaces among them Isolation DO 8 digital output channels (NPN), of which 4 support PWM Isolation AI 2-way (4-20MA, 0-5VDC) Isolation AO 2-way (4-20MA, 0-5VDC) Calculate parameters CPU RK3568J/RK3588 storage 4GB DDR4+16G EMMC 8GB DDR4+32G EMMC operating system Ubuntu22.04 Static power consumption ≤ 15W protect EMC、EMI、 Surge, anti fooling, IP54, industrial grade III Driver module Power supply parameters Power supply voltage The voltage range is 16-36V, independently powered, and can choose to use external DCDC power supply or direct battery power supply Power protection The power input terminal has protection functions such as overvoltage, undervoltage, overcurrent, etc. Exceeding the limited working range will affect the normal operation of the controller. communication interface Non isolated RS485 one Non isolated CAN one Indicator light source one Status lights two Protection function Overvoltage, undervoltage, overcurrent, driver overheating, Hall sensor disconnection output characteristic Rated output current (A) 24V8A Output voltage (V) Output 3-phase under rated conditions, 0V~rated input voltage Output frequency (Hz) 0-1000HZ Overload characteristics 120% rated current for 30 seconds, 300% rated current for 0.5 seconds Standard applicable motor (W) two hundred Motor feedback (HIPERFACE) Hall sensor or ABZ encoder 1 channel/each axis EMC indicators Isolation method Inductive isolation, optocoupler isolation EMC level Industrial Level 3 complete machine Appearance structure Interface distribution Unilateral; Aerial insertion type; Dimensions W x H x D (mm) undetermined Heat dissipation Shell heat dissipation Functional specifications Basic functions Power on mode One click power on/off Power on: Press and hold the power on button until the power on indicator light is on, then release the power on button to complete the power on process. Shutdown: To avoid accidental shutdown in certain scenarios, the controller can press and hold the power on button for 2 seconds before releasing it. Wait for the power on indicator light to turn off and complete the shutdown process. Long press for more than 10 seconds will automatically force the shutdown. The controller supports functions such as digital signal input, digital signal output, and analog signal input. communication Supports standard CANOPEN, MODBUS communication protocols, and custom communication protocols. drive Equipped with 2 * 200W drive output and expandable drive output. Maintainable Data interface communication, signal output control, remote control operation, remote upgrade compatibility Adapted models Rail lifting, ground mounted models, and use on robotic dogs Maintainable Upgradability; With system; Upgrade, control, task, remote deployment Extended functionality system function It has functions such as safe operation control management of mobile robots, decomposition algorithm for robot motion control, control calculation of robot application functions, data acquisition and communication processing. Adapt to multiple mainstream LiDARs and provide rich I/O for connecting various sensors and driver devices. Support secondary development Navigation control Integrated

Product

Drive control integrated machine

classification:

Drive control integrated machine